Looking for something specific?

For fasteners to deliver maximum performance, you need clean, precise holes to accommodate them. Blind rivets, threaded inserts, lockbolts, and other fasteners should fit snugly in a clean hole to prevent pullout, fatigue from movement, and other problems. To drill precise holes, you need precision drill bits.

Choosing the best cutting tools for the job is always a consideration, whether you are setting fasteners in the factory or the field. That includes choosing drill bits from leading manufacturers, such as Champion Cutting Tool Corp.

Read More

Why ATLAS Partners with Bay Supply

ATLAS is one of the best-known makers of fasteners, especially rivet nuts, and the Bay Supply Marketplace offers nearly 6,000 Atlas products. ATLAS has rivet nuts and threaded inserts for every industrial application, although they’re most commonly used in automotive manufacturing and transportation.

Read More

Rivets are always the best type of fastener for the job. Sometimes you want the security of a rivet but may need to remove a part. Or you may have thin or fragile materials that can’t handle conventional rivets. That’s when blind threaded inserts may be a better choice, which means you need the right threaded insert riveter to do the installation.

Read More

When it comes to finding the right fasteners for any job, you have many choices, especially when it comes to rivets. Often, it’s difficult to decide if you want to use a blind rivet, a pop rivet, a solid rivet, or some other type of rivet.

Read More

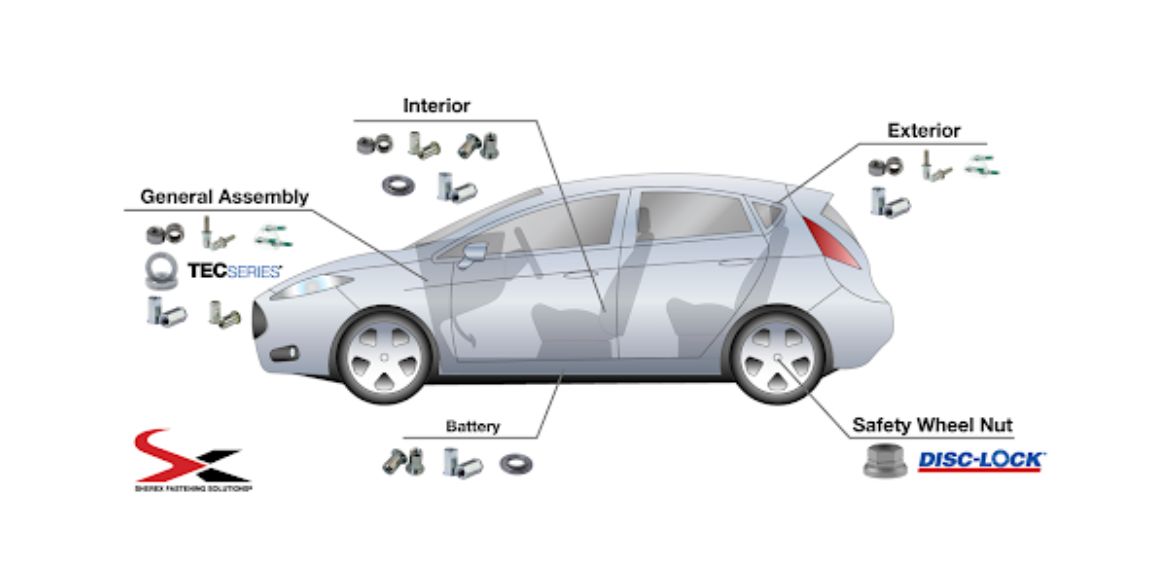

Sherex Fastening Solutions and the Future of Fasteners

Market conditions are continually changing, and new trends lead to demand for new products. To keep pace with changes in the fastener marketplace and shine new light on emerging fastener applications, we decided to start a series of blog posts profiling fastener manufacturers. This post is from our conversation with Adam Pratt, president of Sherex Fastening Solutions, a longtime Bay Supply partner.

Read More

What Are KATO Parts Compatible With?

Helical inserts have become commonplace in manufacturing and repairs. Coiled thread inserts are an ingenious solution to deal with stripped holes or setting a bolt in soft materials. KATO Fastening Systems is one of the companies that has revolutionized helical inserts.

Read Morecurrent_page_num+2: 9 -