Titanium is the ideal material for long-lasting fasteners, and Allied Titanium is the leader in titanium fasteners. Allied Titanium has been designing innovative fasteners for more than 15 years. The company manufactures fasteners for applications such as boat making and marine applications, aerospace, and uses that require a strong and lightweight fastener. You’ll find Allied Titanium’s catalog of titanium fasteners on the Bay Supply Marketplace.

Read MoreLooking for something specific?

Rivets are designed to provide a permanent joint, but sometimes they have to be removed. Maybe a rivet was installed incorrectly or cracked during installation, or perhaps the rivet has started to corrode and needs to be replaced. When you have to remove a rivet, it pays to use the right rivet removal tool.

Read More

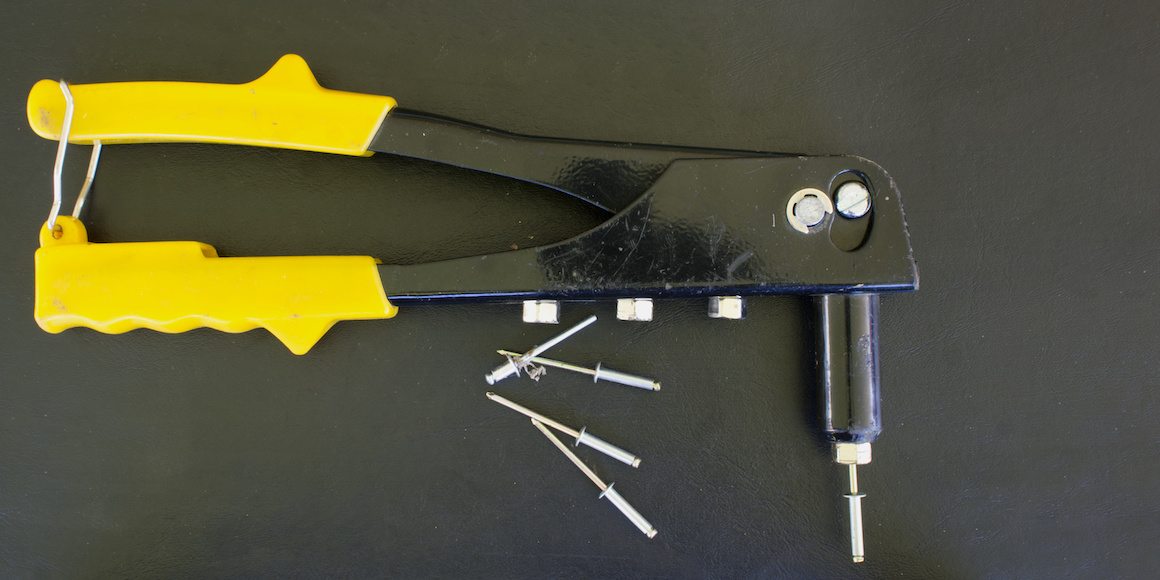

How to Use a Pop Rivet Gun

One of the most popular forms of blind rivets is pop rivets because they are easy to set and extremely strong. Pop rivets can be used for everything from construction applications to manufacturing to making lasting repairs. Pop rivets are effective in wood, metals, and even plastic, but you have to use a pop rivet gun to install them. There are different types of pop rivet tools, and it is important to choose the right tool for the application.

Read More

6 Recommendations for Vibration Resistant Fasteners

Traditional fasteners loosen under vibration. No matter how hard you tighten them, nuts and bolts will loosen with time if they are subjected to regular shaking. In order to solve the problem, engineers developed new types of vibration-resistant fasteners, so today you have a variety of fastener types from which to choose.

Read More

The Difference Between Open and Closed End Blind Rivets and Their Uses

Whether you’re installing an LED sign or repairing a boat, knowing the differences between open- and closed-end rivets is vital. Here are some of the crucial differences to be aware of so you can pick the right blind rivets for your job.

Read More

What are Pop Rivets?

Although the name “pop” is widely used as a generic term for blind rivets, it started out as a brand name for a specific style of rivet patented by the George Tucker Eyelet Company, which was acquired by the United Shoe Machinery Corporation (USM). USM later became part of STANLEY Engineered Fastener, which now owns the POP® trademark.

Read More

Goebel: High Quality Hemlock Blind Rivets, Rivet Nuts and Tools

Goebel Fasteners Inc. is one of the leading makers of threaded inserts and tools. Bay Supply has been an authorized distributor of Goebel threaded inserts and tools for more than a year, and we wanted to share some of the specifics about Goebel threaded inserts and tools so you can see why they are becoming popular.

Read More

What Kind of Power Rivet Gun Do I Need?

With several different types of riveting tools available—manual, pneumatic, and battery-powered—how do you know which is right for your job?

Although manual riveters are great for small jobs, power riveters are key to efficiently meeting production demands and maximizing labor costs. Here are some of the most important considerations to make sure you choose the right tool for your application, as well as our picks for pneumatic and battery-driven power riveters.

Read More

Bay Supply Announces the Launch of Revolutionary Bay-Auto-Quote System for the Fastener Industry

FARMINGDALE, N.Y., July 28, 2023 (Newswire.com) - Bay Supply, the leading Online Marketplace serving the fastener industry, has announced the launch of its innovative Bay-Auto-Quote management system. The new system is designed to streamline and revolutionize how buyers and sellers interact and transact in the fastener industry.

Read Morecurrent_page_num+2: 8 -