Rivet tools come in different configurations with different power profiles. While toolmakers have been focusing on developing a new generation of lighter, portable tools, structural blind rivet tools remain in high demand. There are no better tools for critical product assembly, maintenance, metalwork, truck and transit work, and setting industrial rivets.

Read MoreLooking for something specific?

Six Things to Look for When Buying Fasteners Online

Rivets, blind fasteners, and lockbolts may seem to be insignificant, but they are literally the parts that hold things together. Whether you work in manufacturing, construction, shipbuilding, solar installation, or another industry, having the right fastener in stock is what keeps you productive. More professionals are purchasing fasteners online to find the parts they need when they need them.

Read More

Matching the Best Fasteners to 7 Industrial Applications

Manufacturers need different types of fasteners for industrial applications. Some jobs require closed-end rivets, and others need trifold rivets. Other products use general-purpose and high-clamp assemblies. You want to choose the right industrial fastener, whether you are manufacturing appliances, assembling recreational vehicles, or building computers. You also want to choose industrial fastener brands that work well together to ensure lasting performance.

Read More

5 Common Misconceptions About How Blind Rivets Work

Blind rivets have been used for more than 100 years, but they’re still misunderstood. British inventor Hamilton Neil Wylie first patented the blind rivet design in 1916. Since then, blind fasteners have been used for everything from making automobiles to manufacturing appliances.

Read More

Rivets have been used for millennia for everything from shipbuilding to construction. As long as humans have been building with rivets, there have been rivet tools.

The earliest rivet tool was a hammer, used to drive rivets through pre-drilled holes. As fastener technology has progressed, new materials and rivet designs have called for new rivet tools.

Fasteners are essential components in automobile manufacturing and repair. Bolts, rivets, blind bolts, screws, washers, and other components hold a car together, so it’s essential to choose the right fastener for each application.

Read More

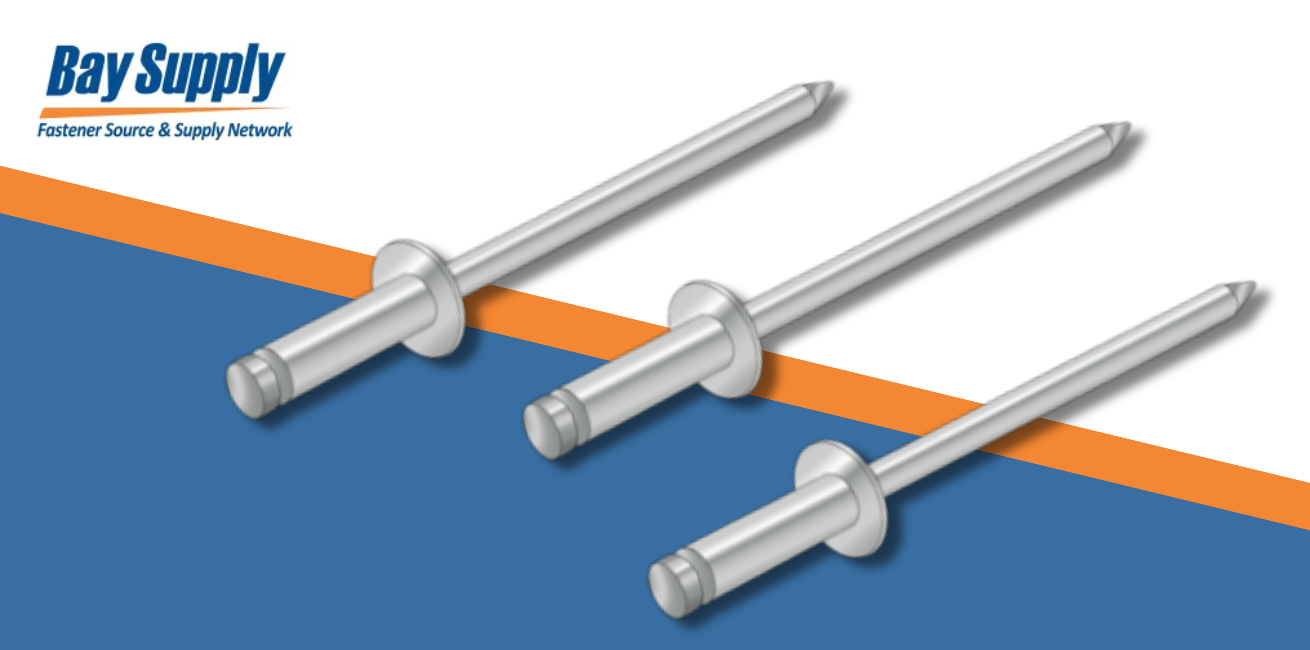

An Overview of Breakstem Rivets

Breakstem rivets have become the mainstay of the fastener industry. Commonly referred to as blind rivets or pop rivets, breakstem rivets are used for everything from patio furniture to construction.

Breakstem rivetsare so popular because of how versatile they are. They come in different sizes and materials and can handle multiple grip ranges. They are also easy to install using either manual or power tools.

Read More

When Should I Use a Mate Rivet?

When you think about rivets, you usually think about one-piece fasteners designed to join two pieces of material. Solid rivets are designed to be installed using a bucking bar to flatten one end. There are also blind rivets designed with a shaft and a mandrel that you pull to form a secure joint on the blind side of a workpiece. These types of rivets are one-piece fasteners that are easy to install.

Read More

Can You Install Grooved Blind Rivets in Plastic?

When and Where to Install Easy Entry Rivets

We have been blogging recently about easy entry rivets, what makes them unique, and how to use them. In this blog post, we want to delve deeper and discuss where to use them.

Read Morecurrent_page_num+2: 3 -