Keeping the necessary parts in stock is an ongoing challenge for any manufacturer. Running out of parts stops production, so effective inventory management is vital. If you run out of critical parts, such as fasteners, productivity slows as the product team scrambles to track down additional inventory, which you will end up paying more for.

Read MoreLooking for something specific?

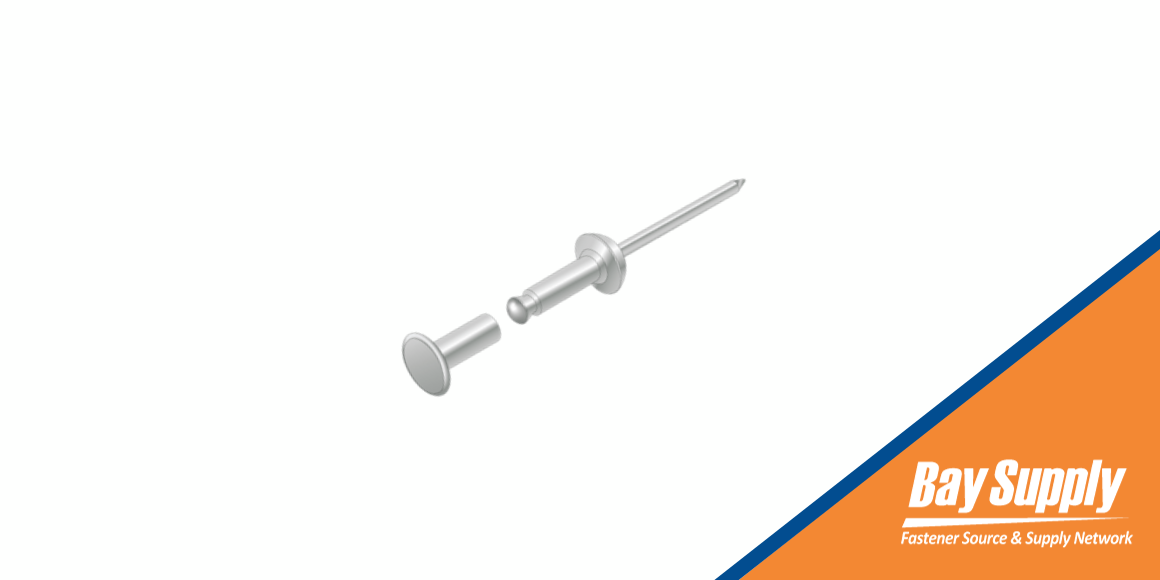

Rivets provide a permanent joint between two pieces of material—for example, airplane skins or solar panels—by pressing the material together. When you have thinner materials and want a firm joint, conventional rivets or blind rivets work well. However, sometimes you need rivets that have a longer grip length or can serve as a pivot point. In such cases, it makes sense to use mate rivets, sometimes called Cherrymate rivets or semi-tubular rivets.

Read More

Blind fasteners are available for every application imaginable, from building cars and trucks to installing circuit boards. Choosing a suitable blind fastener for the job means matching the fastener to the materials. You want to select a fastener that delivers optimal performance, whether you’re installing fasteners in steel, wood, or plastic.

Read More

Blind rivets are a category of fastener that encompasses various designs beyond the simple pop rivets. Most blind rivets have a two-piece design with a rivet body and a mandrel insert. They are commonly used in manufacturing, HVAC, boat building, construction, and any application where you must fasten two materials together but only have access to one side. The ability to set a rivet without access to the back—or blind side—is where the term blind rivet derives from.

Read More

When we think about constructing ships or airplanes, we may visualize large industrial equipment and machinery compiling sizable masses of metal. However, the smallest pieces of hardware can make a big difference in the functionality of these common commercial products.

Read More

8 Ways to Prioritize Safety in Workplace Management

On-the-job safety is everyone’s concern, but when maintaining a safe workplace or job site, it’s up to management to implement policies and procedures to keep everyone safe. Much of on-the-job safety stems from common sense, but without guidelines or protocols, common sense is not enough. Everyone needs to adhere to an established set of safety rules to promote an injury-free job site.

Read More

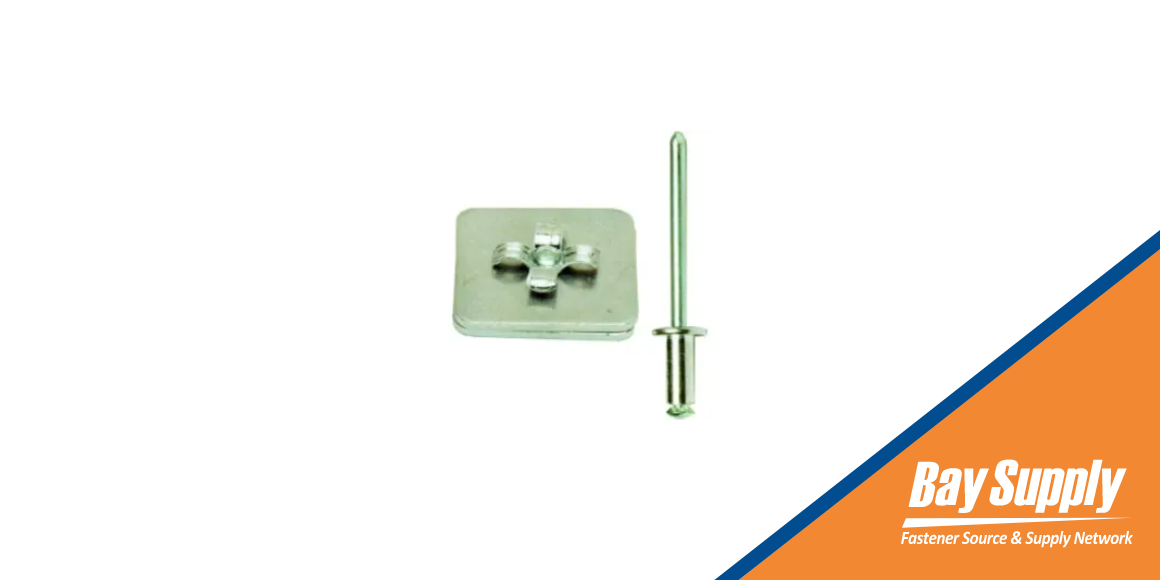

Rivet Nut Uses and Installation Tips

With some projects, finding a fastener that works with thin or brittle materials can seem impossible. This is where rivet nuts, which are also known as a blind nuts, blind rivet nuts, or threaded inserts, come in. A variation on the standard rivet, the rivet nut has a tubular round, splined, square, or hexagonal body that is internally threaded and counterbored. As a blind fastener, the rivet nut is installed in instances where only one side of the workpiece is accessible, making it incredibly versatile.

Solid rivets are perhaps the oldest known fastener. Rivets have been found in archaeological sites and are still used in construction, manufacturing, aerospace, automotive, boat building, and for hundreds of other applications. Rivets outperform screws, bolts, and even welds, but rivets must be properly installed to create a tight and lasting joint.

Read More

For fasteners to deliver maximum performance, you need clean, precise holes to accommodate them. Blind rivets, threaded inserts, lockbolts, and other fasteners should fit snugly in a clean hole to prevent pullout, fatigue from movement, and other problems. To drill precise holes, you need precision drill bits.

Choosing the best cutting tools for the job is always a consideration, whether you are setting fasteners in the factory or the field. That includes choosing drill bits from leading manufacturers, such as Champion Cutting Tool Corp.

Read Morecurrent_page_num+2: 3 - disabled