Rivets provide a permanent joint between two pieces of material—for example, airplane skins or solar panels—by pressing the material together. When you have thinner materials and want a firm joint, conventional rivets or blind rivets work well. However, sometimes you need rivets that have a longer grip length or can serve as a pivot point. In such cases, it makes sense to use mate rivets, sometimes called Cherrymate rivets or semi-tubular rivets.

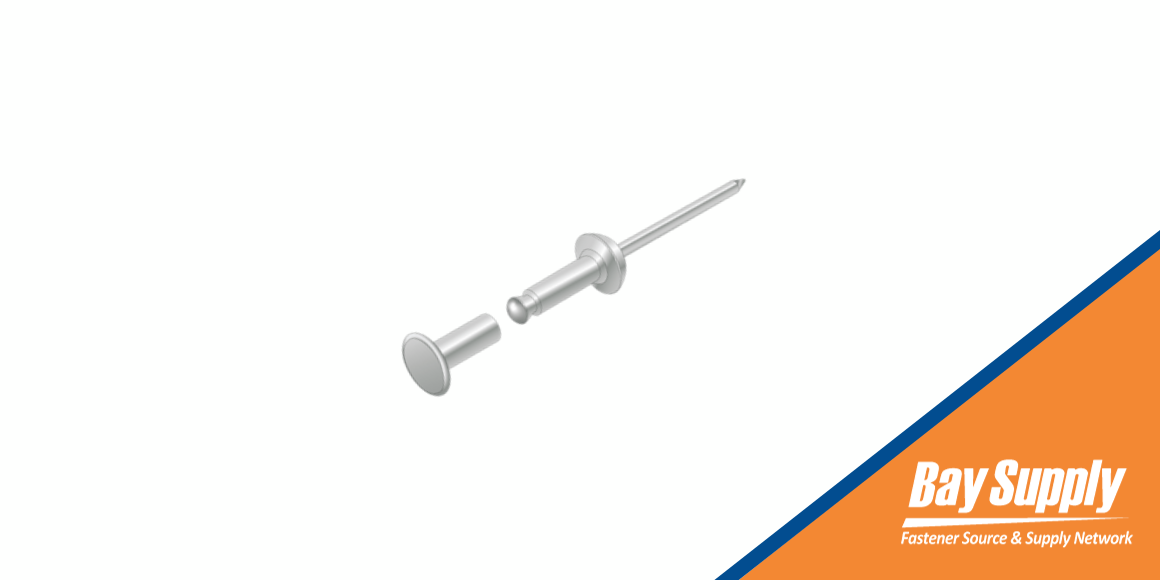

A mate rivet has a similar design to other rivets. It has a rivet body, and a mandrel is pulled to install the rivet. What makes mate rivets different is the tubular mate used to install the rivet. When installed, the mate rivet body fits inside the tubular mate piece. When the mandrel is pulled, the rivet body expands and is secured inside the mate piece to form the joint.

Mate rivets are often used instead of nuts and bolts because they are tamperproof and won’t loosen over time. They are also commonly used where a fastener with a longer grip range is required.

Applications for Mate Rivets

Mate rivets’ unique design makes them the ideal fastener when, for example, you want a strong fastening that can be used as a pivot, such as for playground equipment. Mate rivets are also used for bathroom stalls or other assemblies where you want a tamperproof fastener.

Mate rivets were originally developed by Cherry Aerospace, which started as the Cherry Rivet Company in Los Angeles in 1940. Carl Cherry designed the first blind rivets used in aircraft manufacturing, and the Cherry Mate Rivet evolved from the original blind rivet design.

What makes mate rivets attractive is their superior performance. They are tamperproof and vibration-resistant, so they won’t torque out or loosen up like threaded fasteners. Hole size is less critical with mate rivets than other rivets, making drilling and installation easier. Because the mandrel expands inside the mate tube while you control the fastener tension, there is no concern about crushing the material; this is why mate rivets can be used for leather, clothing, and soft goods. Mate rivets can also be installed using handheld or power tools for maximum versatility.

The mate rivet’s tubular design is useful for various applications, such as ducts, light fixtures, binders, luggage, leather goods, electronics, and street signs. Mate rivets also have a smooth finish, which makes them suitable for applications such as truck trailers, fences, and livestock pens. They also work well with plastic seats or PVC pipe because they create a firm, lasting joint and won’t corrode. Consider using mate rivets for any application needing a longer, tamperproof fastener.

Installing Mate Rivets

Mate rivets are installed much like any other type of rivet. The only difference is that the installation must accommodate the mate piece, which means you need access to both sides of the material.

Start with the tubular or mate piece and insert it from one side of the material. Then, insert the rivet into the mate piece. Pull the mandrel as you would with any rivet, and the mandrel will expand inside the mate piece to form a secure joint without crushing the parent material. The joint is finished when the mandrel is broken off and removed.

The trick to properly installing mate rivets is ensuring they are snug before installation. Mate rivets have a broader grip range, so the joint must be tight enough to eliminate movement or play.

Mate rivets can be installed with pneumatic tools, battery-powered rivet tools, manual tools, or a hammer and bucking bar. Mate rivets only require about one-quarter of the force it takes to install conventional blind rivets, so it’s essential to set the installation pressure so as not to crush the parent materials, especially with soft or brittle materials.

Choosing the Right Mate Rivets

As with all rivets, choosing the proper mate rivet is a matter of selecting the best diameter and length.

When choosing the best diameter, you want to use the diameter of the semi-tubular mate piece because that is the section that fits through the hole. Diameters are 0.187 inches and up.

Grip ranges scale to fasten materials up to four inches thick. You have some flexibility in choosing the rivet length, but you must be sure the grip range falls within your application's tolerance. If the mate rivet is too long, the joint will be loose. If the rivet is too short, the joint won’t be secure.

Mate rivets are also available in different materials. All-aluminum rivets are common, although manufacturers also make steel-alloy mate rivets or rivets made with aluminum sleeves and steel stems. Special coatings are available to prevent corrosion.

For applications that require long-term durability, such as mounting street signs or manufacturing luggage, mate rivets are the perfect choice because they provide reliable, lasting performance without marring the materials. They are also well suited for applications requiring a longer grip range, such as connecting poles or beams.

To find the best mate rivet for your application, shop at the Bay Supply Marketplace and see the wide selection of available mate rivets.

Comments