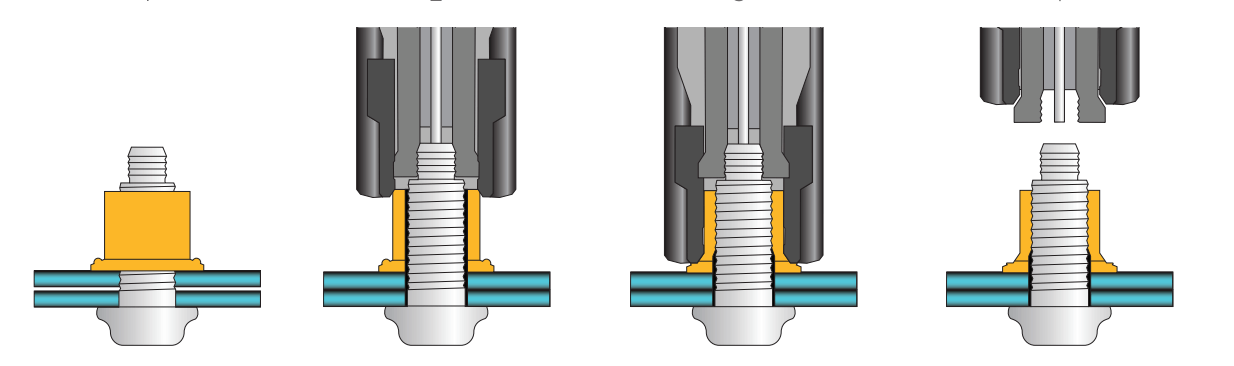

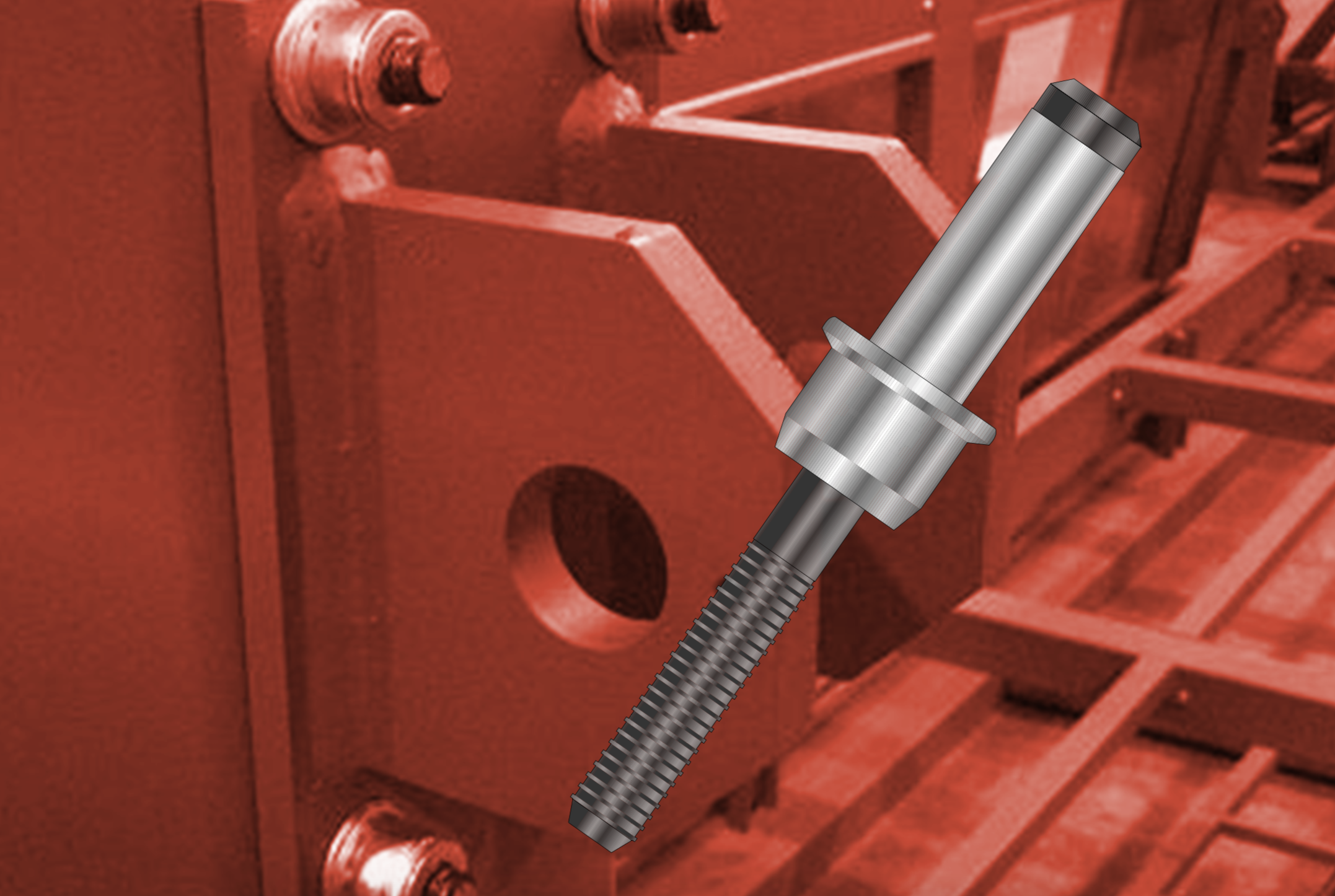

Lockbolts are the preferred fastener for tough environments because, once installed, they won’t loosen, even under the toughest conditions such as continuous stress or vibration. The two-piece lockbolt consists of a grooved pin and a sleeve, and once installation is complete, the sleeve is permanently fixed so it can only be removed with a special cutting tool.

Read MoreLooking for something specific?

6 Benefits of Using a Lockbolt

Lockbolts have become one of the most popular types of fasteners for manufacturing, construction, transportation, mining, and a variety of other applications. There are many benefits of lockbolts, and they have proven to be a durable and lasting fastener solution in most applications.

Read More

What is a Lockbolt?

Read MoreLockbolts are just what they sound like—bolts that lock in place when installed so they won’t loosen over time, even with extreme stress and vibration. Lockbolts are used in a variety of applications in place of a rivet or conventional bolt because of their superior strength and lasting performance.

When you need a fastener that is easy to install and designed to last, there is nothing like a blind bolt. Blind bolts are used in place of welds or other types of joints, allowing you to clamp materials together for a lasting joint. They have become common for use in aircraft and automotive manufacturing and in heavy-duty applications such as mining, trucking, and construction.

Read More

KATO Fastening Systems: Offering Quality Helical Inserts and Tools

Helical inserts are the most innovative and secure means of installing fasteners in stripped screw holes or soft materials. Bay Supply carries a variety of helical inserts and helical coil products, and Kato Fastening Systems inserts continue to be a top seller because they provide permanent, wear-resistant threads for almost any job.

Read More

A rivet nut is a unique type of rivet, sometimes known as a blind rivet nut, a threaded insert, a rivnut, or a nutsert. It is tubular, internally threaded, and counterbored so it can be driven just like a blind rivet from one side. However, there are various types of rivet nuts from multiple manufacturers, so it’s important to understand some of the nuances.

Read More

4 Considerations When Buying Multi-Grip Rivets Online

Precision is essential for many manufacturing and construction applications. Sometimes the required precision can vary across applications, and even among different areas of the same application.

Read More

How the Metal Price Hikes are Affecting These 6 Industries

Metal price hikes, primarily caused by tariffs imposed by the Trump administration, have resulted in major headaches for American companies. How prices will be affected in the future remains uncertain.

Read More

Whether you oversee an assembly line, manage a repair shop, or are a do-it-yourself enthusiast, you always want to use the right tool for any task at hand. Failing to follow this basic principle can dent productivity and negatively affect the quality of whatever you are constructing or repairing. That’s disappointing for a DIY fan or hobbyist and it’s costly for a business.

Read More

The idea of rivets and heavy-duty metal fasteners often conjures up images of serious industrial uses: airplanes, skyscrapers, bridges, and assembly lines. However, rivets also offer functionality and durability for a wide variety of home improvement projects and goals.

Read Morecurrent_page_num+2: 15 -