For some applications, a tight seal plugging a hole isn’t a luxury—it’s mandatory. Leaks of air or fluid are simply not acceptable, and you must have confidence that the seal you supply will perform as expected, even if you don’t have access to one side of the hole during installation.

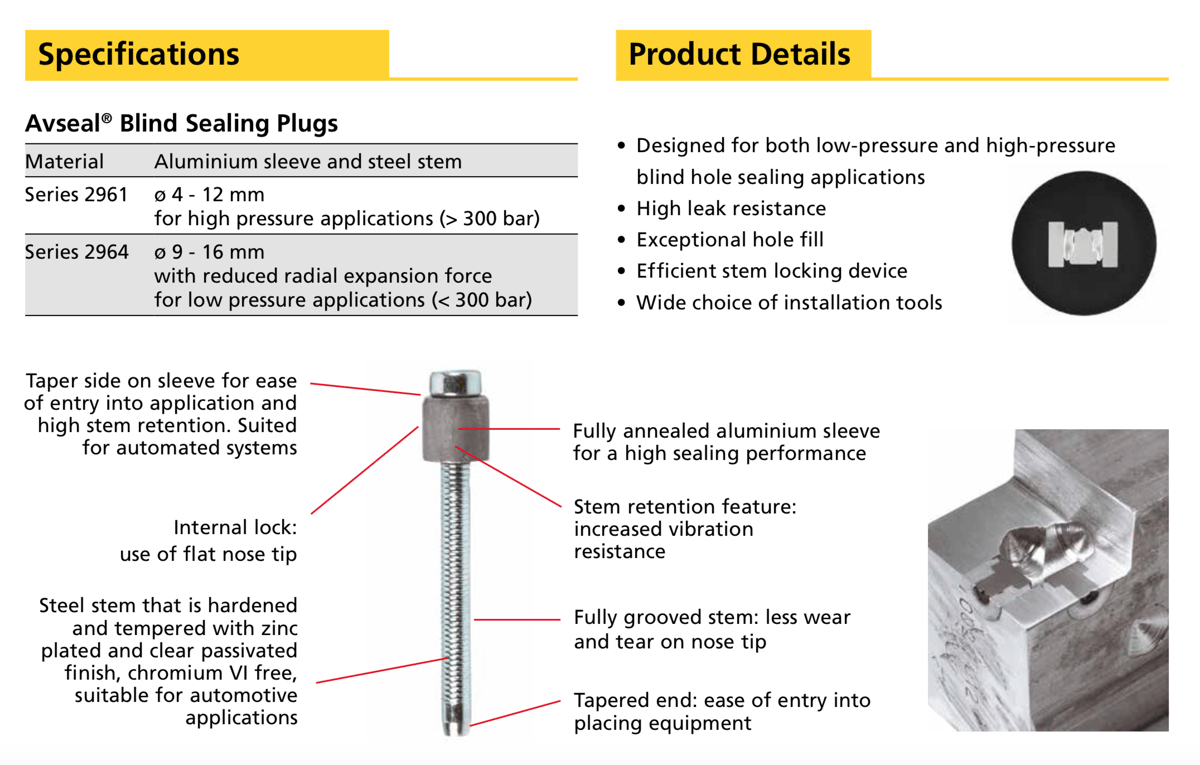

The solution to this scenario might be an Avseal. Produced by Avdel, an Avseal is a two-piece blind sealing plug that fills holes in thin metal components in low- and high-pressure applications. The technology has advanced to the second generation, and the Avseal II is even more effective with poorly prepared and oversized holes.

Here’s more information about Avseals and how they can boost your sealing needs:

Avseals, Explained

Cross drilling in castings present a unique challenge in effectively sealing the hole. Threading a plug into the hole, welding the hole, press-fitting it with pins, or filling it with steel balls are measures that can be taken to seal the hole, but none of these processes is reliable, and all require extra time and expense to complete, thus slowing down assembly.

Avseals were created to deliver a high-performing, pressure-tight (up to 500 bar) seal that could be applied efficiently and expediently. The two-piece (steel mandrel and aluminum sleeve) plug is placed onto a rivet gun and into the blind hole. Upon pulling the trigger, the sleeve is compressed and expands to form the seal. The pintail breaks away and leaves the plug even with the assembly’s surface—and sealed tight.

The process is efficient because it doesn’t require any preparation of the hole (e.g., thread tapping). Moreover, Avseals can be applied with a standard Avdel rivet gun—there’s no need to purchase or train on extra equipment. Subsequently, no advanced skills are needed to apply; as long as you can place the seal onto the rivet gun, point, and shoot, you can install an Avseal. This saves time and removes the worry that a traditional seal might fail simply because of the work involved to place it.

The Avseal II is available in sizes of 4-12 millimeters for high-pressure applications (more than 300 bar) and 9-16 millimeters for low-pressure applications. They are ideal for:

- Thin-wall applications

- Restricted space

- Shorter hole length

- High-pressure applications

- Holes with large tolerance

Also, Avseals can be removed with a specialized tool and then replaced as needed.

Benefits and Features of Avseals

The advantages of using an Avseal go beyond a tighter seal and efficiency. Additional benefits and features include:

- Fully annealed aluminum sleeve for high sealing performance

- Tapered end for easy entry into placing equipment

- Increased vibration resistance

- Flat nose tip

- Tapered side on sleeve for easy entry into the hole and high stem retention

- Blind-hole, one-sided installation capability

- Seal quality not operator-dependent

- Available as a customized design to meet unique assembly requirements

- No locking ring formed by nose tip, thus reducing preventative maintenance

- Reduced radial expansion force with low-pressure Avseals

- Shorter placed length for reduced blind-side protrusion

- Suitable for ferrous and alloy materials

- Tolerance for a wide range of operating temperatures

Practical Avseal Uses

The applications that benefit from Avseals are plentiful. For automotive assembly, the seals can be used in:

- Engine blocks

- Transmissions

- Cylinders

- Brakes

- Clutches

- Gear boxes

- Suspensions

- Fuel injection systems

Industrial applications that benefit from Avseals include:

- Fluid handling

- Pneumatic systems

- Hydraulic blocks

- Compressors

- Refrigeration

- Pumps

- Conveyor technology

- Mold construction

If you are unsure whether Avseals are suited for your particular application, a top-notch distributor can help. The best partners will have a range of sizes available for your job, can identify if you have the correct tools for installation, and will offer advice and resources for using this impressive technology.

Comments