When you have a large assembly job that requires lots of blind rivets, there is nothing like a speed fastening system to shorten time to completion. As a fastener distributor, we work with all types of fasteners and fastener systems, and we have seen how speed fasteners save our customers time and money. And just as it is important to match the right fastener to the job, you also have to match the right speed installation setup to the task.

Read MoreLooking for something specific?

Recent Posts by Mike Eichinger - COO, Bay Fastening Systems

Essential Definition: What Is a Speed Fastening System?

In every industry, time is money. The more time it takes to complete any task, the more time it takes to complete the job and the more that job costs. In manufacturing, construction, repair work, and related fields, efficiency matters; the less time it takes to get the job done, the more you can produce and the more you can lower your costs. That’s why fastener distributors are seeing more demand for Speed Fastening systems.

Read More

Two Series of Pneumatic Lobster Tools You Should Know About

Just as there are many choices when it comes to blind fasteners and rivets, there also are a variety of blind rivet tools to install them. Tools come in different configurations, and each type of tool has its unique advantages and applications. Pneumatic riveters are particularly useful for production lines and construction projects, and Lobtex Co., Ltd. of Japan is one of the newest companies to enter the riveter market with its pneumatic Lobster tool. We cover more about Lobster tools and how they fit into the bigger picture of riveting tools.

Read More

Blind fasteners have been around for decades, but manufacturers continue to find new ways to improve them. They make them out of better materials with improved designs and new features and benefits that make them easier to use. One of the most popular and reliable fasteners is the Huck BOM® blind fastener.

Read More

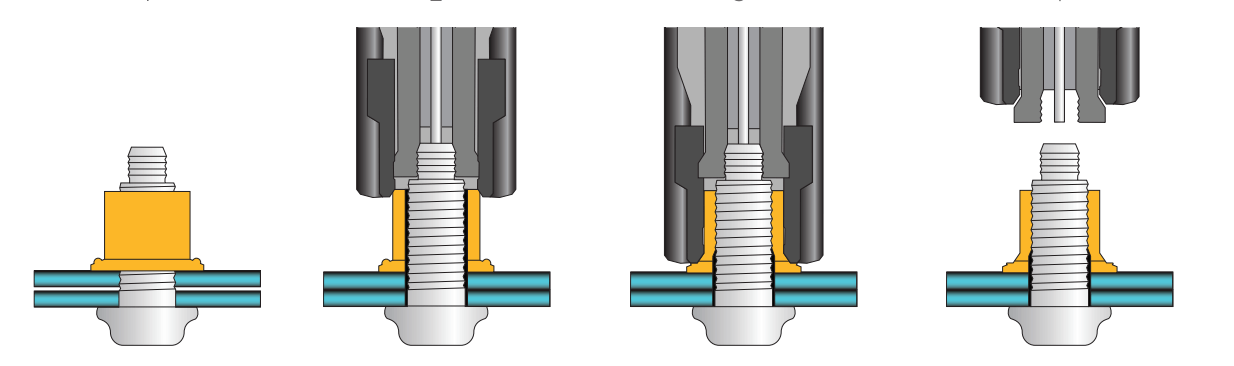

Reviewing Proper Installation of a Lockbolt and Lockbolt Tools

Lockbolts are the preferred fastener for tough environments because, once installed, they won’t loosen, even under the toughest conditions such as continuous stress or vibration. The two-piece lockbolt consists of a grooved pin and a sleeve, and once installation is complete, the sleeve is permanently fixed so it can only be removed with a special cutting tool.

Read More

6 Benefits of Using a Lockbolt

Lockbolts have become one of the most popular types of fasteners for manufacturing, construction, transportation, mining, and a variety of other applications. There are many benefits of lockbolts, and they have proven to be a durable and lasting fastener solution in most applications.

Read More

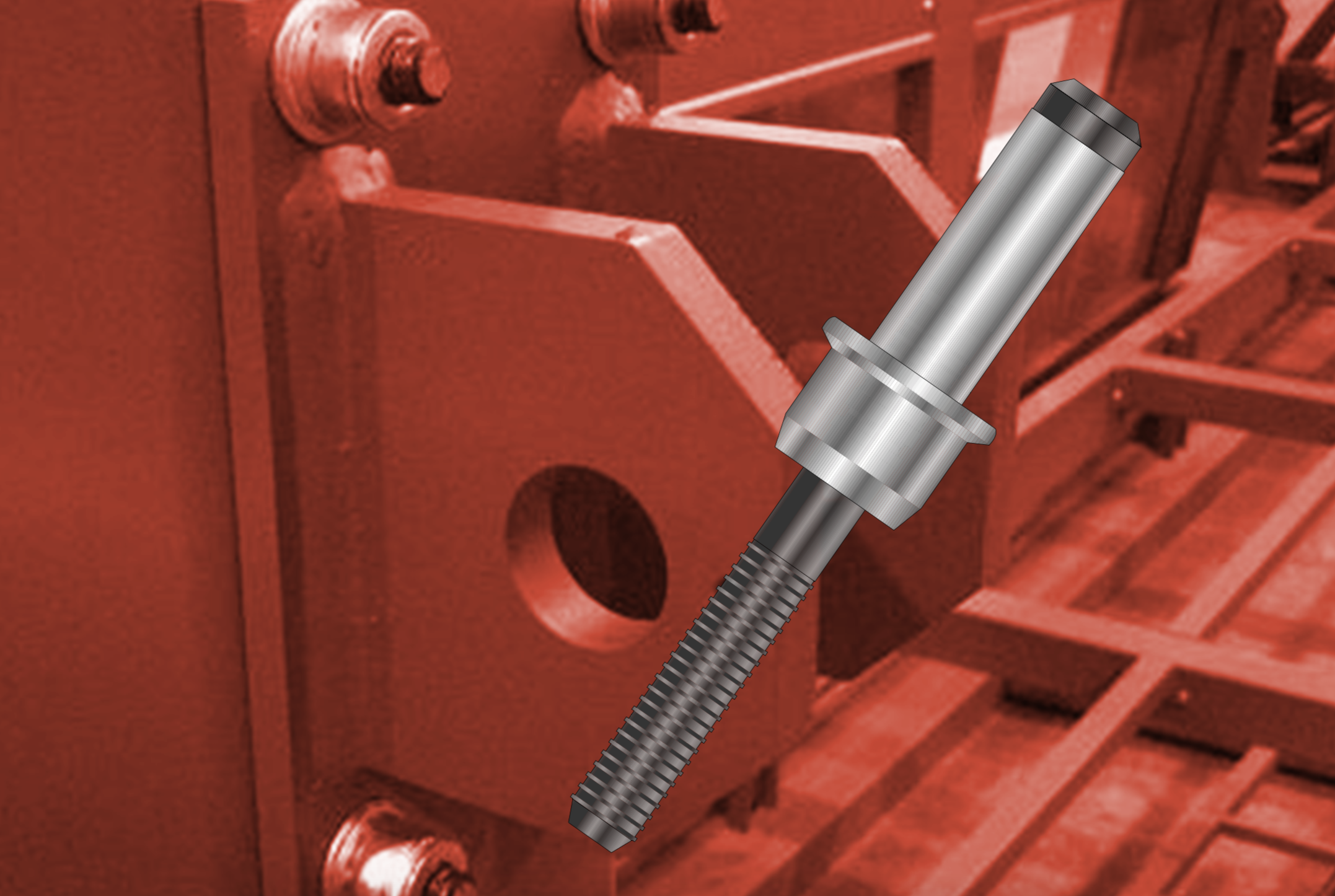

What is a Lockbolt?

Read MoreLockbolts are just what they sound like—bolts that lock in place when installed so they won’t loosen over time, even with extreme stress and vibration. Lockbolts are used in a variety of applications in place of a rivet or conventional bolt because of their superior strength and lasting performance.

When you need a fastener that is easy to install and designed to last, there is nothing like a blind bolt. Blind bolts are used in place of welds or other types of joints, allowing you to clamp materials together for a lasting joint. They have become common for use in aircraft and automotive manufacturing and in heavy-duty applications such as mining, trucking, and construction.

Read More

KATO Fastening Systems: Offering Quality Helical Inserts and Tools

Helical inserts are the most innovative and secure means of installing fasteners in stripped screw holes or soft materials. Bay Supply carries a variety of helical inserts and helical coil products, and Kato Fastening Systems inserts continue to be a top seller because they provide permanent, wear-resistant threads for almost any job.

Read More

A rivet nut is a unique type of rivet, sometimes known as a blind rivet nut, a threaded insert, a rivnut, or a nutsert. It is tubular, internally threaded, and counterbored so it can be driven just like a blind rivet from one side. However, there are various types of rivet nuts from multiple manufacturers, so it’s important to understand some of the nuances.

Read Morecurrent_page_num+2: 14 -