Threaded rivet nut inserts are a specific type of fastener designed to provide a threaded hole that can accept a bolt or threaded fastener. As with any type of fastener, there is more than one configuration, each designed for specific applications. The well nut is just one threaded rivet nut insert with a unique design and was created for particular uses.

Read MoreLooking for something specific?

Recent Posts by Mike Eichinger - COO, Bay Fastening Systems

There are different fasteners for different applications. If you want a permanent bond, rivets or blind bolts may be your best option. A rivet nut may be a better choice if you want a strong join that can be set with a screw so it can be serviced or replaced.

Read More

Keys to Evaluating Threaded Inserts for Plastic

Plastics have been part of our lives since the 1950s and have become integral in manufacturing and industrial applications. However, bonding plastics with different plastics or other materials is one particularly challenging aspect of working with plastics. One of the most common and durable techniques for bonding plastic components is with threaded inserts for plastics.

Read More

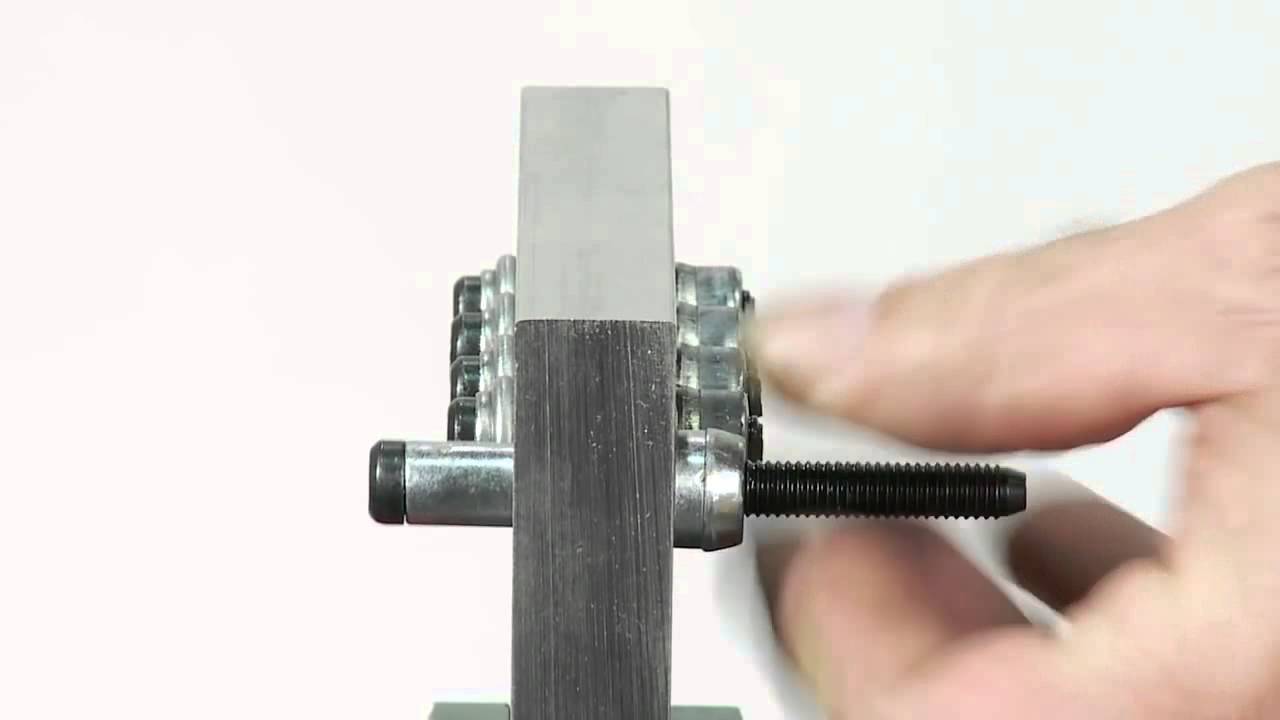

What Kind of Manual Riveter Do I Need? The Right Tool For the Job

When shopping for rivet tools, you want to consider the tool's weight, pull force, power source, and other specifications. For example, battery-powered rivet tools might be better suited for construction jobs or applications in which you need more portability, whereas pneumatic tools are better in a factory setting or heavy-duty assembly. There also are times when you want a manual rivet tool, particularly for simple jobs that don’t need a high-impact installation. It’s also useful to have a manual rivet tool on hand for simple repairs or smaller jobs. So the question is: Which tool do you choose?

Read More

Why Manufacturers Should Care About B2B Vertical Marketplaces

E-commerce is no longer a new concept. Consumers have been buying goods online for years, and since the pandemic, online sales have been rising faster than in-store sales. According to the U.S. Department of Commerce, total retail sales saw a 6.9 percent increase in Q4 2020, and e-commerce sales rose 32.1 percent in the same period. Today, e-commerce sales make up about 14 percent of overall retail sales.

Read More

Blind bolt fasteners continue to gain popularity because they offer cost-effective performance. They can secure short clamp lengths and create a lasting bond. They stand up well in high-stress applications, including when there’s heavy and constant vibration. Blind bolts are also quick and easy to install. In fact, with the right blind bolt fastener tool, they can be installed at rates from 150-500 pieces per hour.

Read Morecurrent_page_num+2: 10 -