There are specialty fasteners for every conceivable application, including fasteners that seal out moisture and can withstand harsh environments. For critical applications in aircraft, robotics, automobiles, military equipment, manufacturing, marine environments, and construction, you need fasteners that resist corrosion, withstand pressure fluctuations, and deliver lasting performance. That’s when engineers prefer ZAGO fasteners.

Read MoreLooking for something specific?

Recent Posts by Mike Eichinger - COO, Bay Fastening Systems

.png)

Why Coil Thread Inserts Are Unique Among Fasteners

Threaded fasteners need a solid substrate for lasting performance. The threads must be solidly anchored in the material without loosening or pullout, which can be challenging with softer materials, such as wood and plastics. Threaded holes can also become stripped over time, requiring some way to restore the threads.

Read More

Emerging industries are continually finding new applications for commercial fasteners. The market for commercial solar installations has been booming in recent years, and manufacturers such as Howmet Aerospace have been developing new Huck brand adapters specifically for installing solar arrays. One of the latest innovations is the Huck BOMtail, designed specifically for commercial solar panels and trackers.

Read More

Accelerating Assembly with Speed Fasteners

Chances are, you will find fasteners used to assemble products in every factory. Nuts, bolts, anchors, lockbolts, and other industrial fasteners are essential to manufacturing everything from computers to airplanes.

Production lines that use precision manual processes tend to be slow and require workers to set and inspect fasteners one at a time. Automating the process saves time, labor, and money. However, to automate production, you need speed fasteners that shorten assembly time while ensuring consistent quality.

Read More

Huck Is Forever: Achieving Enduring Strength in Industrial Fastening Applications

When it comes to industrial fasteners, the primary goal is to create secure and lasting joints. Superior performance is the criterion for choosing the best fastener for any application. The fastener must maintain joint integrity over time, especially for applications in which added stress and joint failure could be disastrous. That’s why Huck fasteners have become so popular.

Read More

Fascomp Built Its Business on Distribution

Rivets, lockbolts, blind bolts, and other fasteners are incredibly versatile and can be used for various applications, but sometimes, you need a specialty fastener designed for the task. Fascomp is a specialty fastener maker that creates electronic hardware specifically designed for electronics installations and components.

Read More

Fasteners and Tools for Automated Warehouse Construction

Technology has changed the retail business, and it continues to do so. Rather than ordering goods from a catalog or local store and waiting for them to be delivered, orders are now fulfilled overnight. Large retailers, such as Amazon and Walmart, even offer same-day delivery in some regions.

Read More

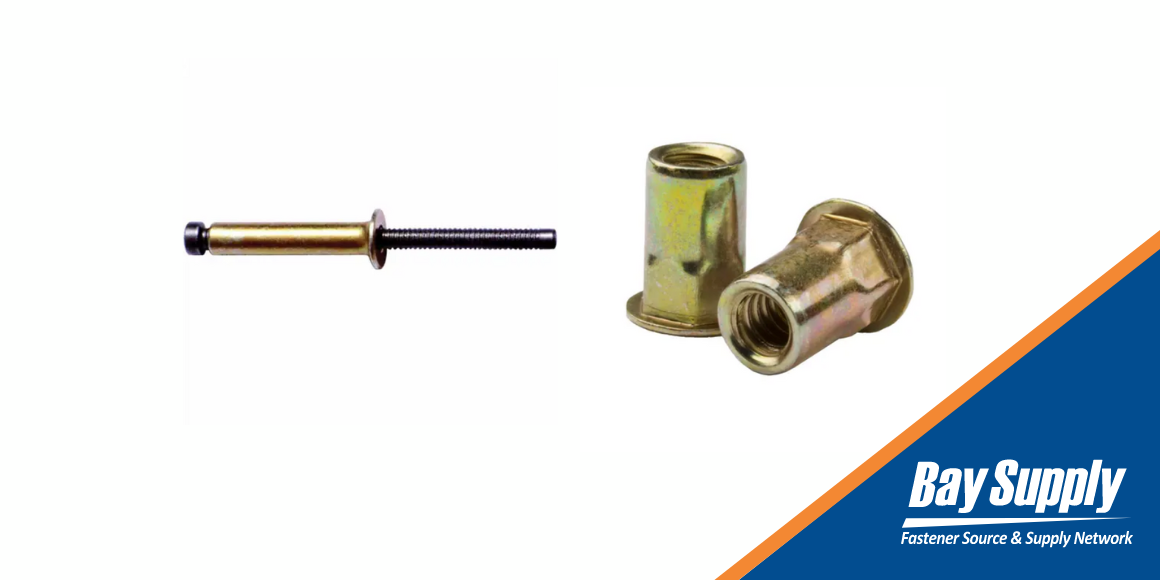

Rivets, Lockbolts, and Fastener Tools Suited for Solar Installations

The solar industry is booming thanks to growing concerns about climate change and an increasing demand for alternative energy sources. The increased demand for solar panels and commercial solar installations is also creating a new demand for specialty fasteners that are easy to install and durable.

Read More

Rivets have been used for millennia for everything from shipbuilding to construction. As long as humans have been building with rivets, there have been rivet tools.

The earliest rivet tool was a hammer, used to drive rivets through pre-drilled holes. As fastener technology has progressed, new materials and rivet designs have called for new rivet tools.

Fasteners are essential components in automobile manufacturing and repair. Bolts, rivets, blind bolts, screws, washers, and other components hold a car together, so it’s essential to choose the right fastener for each application.

Read Morecurrent_page_num+2: 4 -