Blind bolt fasteners continue to gain popularity because they offer cost-effective performance. They can secure short clamp lengths and create a lasting bond. They stand up well in high-stress applications, including when there’s heavy and constant vibration. Blind bolts are also quick and easy to install. In fact, with the right blind bolt fastener tool, they can be installed at rates from 150-500 pieces per hour.

Despite these benefits, however, proper installation is important to get optimal performance out of any blind bolt. For example, you must ensure the bolt properly fits the pre-drilled hole to create a solid joint. You also need to apply sufficient pressure upon installation, otherwise the bolt will not get a solid seal on the blind side.

Using the right tool for the job often mitigates many of these errors. Because there are nearly as many types of blind bolt fastener tools as there are blind bolt fasteners, you must first appreciate the differences in tool design and performance to make the right choice.

Types of Blind Bolt Fasteners

To choose the right blind bolt fastener tool, you must consider the types of fasteners you will be using and the type of installation. For example, tools used in a factory setting will differ from those used in building construction or on a job site.

Two of the most common blind bolt fasteners on the market are the Huck BOM® blind bolt and the Avdel® Avbolt steel blind bolt.

Huck BOM® Blind Bolt

The Huck BOM® blind bolt is perfect for high-stress applications. Once installed it won’t work loose, unlike conventional nuts and bolts, and its thread form resists fatigue. These types of blind bolt fasteners are often used for heavy vibration applications such as rail cars, auto suspensions, military equipment, and factory equipment. They also are tamper-resistant because they require special tools to remove.

The Avdel® Avbolt Steel Blind Bolt

The Avdel® Avbolt steel blind bolt is often chosen for commercial applications where high performance is needed, such as heavy-duty construction and product assemblies. These bolts were designed for applications such as manufacturing ships, mining equipment, and ground transportation, providing a strong, lasting joint that is durable against continuous vibration.

Types of Blind Bolt Fastener Tools

Blind bolt fastener tools come in two basic configurations:

- Pneudraulic fastener tools use compressed air connected by a single air hose to an air compressor. They come with different nose assemblies that can be fitted to accommodate different fastener sizes. They take little or no training to operate.

- Hydraulic fastener tools are powered by multiple hydraulic hoses connected to fluid pumps that are triggered by a low-voltage electric control. Hydraulic-powered tools deliver a lot more power and require fluid adjustments for proper operation so they require operators with special training.

Bay Supply carries a variety of blind bolt tools, including:

Avdel 7300

The Avdel 7300 is a pneudraulic tool that delivers air pressure between 75-100 psi and a 0.79-inch stroke, which gives it a pull force from 6,823-8,138 pounds. It has a three-second cycle time and only weighs 10 pounds (without the nose hardware), so it is light enough to be used for handheld installations.

Avdel Enerpac Power Unit Pro115E and Pro220E

The Avdel Enerpac Pro units have high-efficiency motors that deliver an operating pressure of up to 10,000 psi. They also feature self-contained hydraulic pump units and are designed to operate at either 115 volts (Pro115E) or 220 volts (Pro220E). They also weigh in at 70-115 pounds.

Huck 254

The Huck 254 is a pneudraulic riveter that combines air and hydraulic fluid for power with a cycle time of 30 bolts per minute. It features a 0.565-inch stroke and a pull capacity of 8,620 pounds, weighing in at 8.67 pounds.

Huck 256

The Huck 256 also is a pneudraulic riveter with a 0.875-inch stroke and is perfect for one-cycle installation. This tool is designed to be used in high-speed production and can set up to 20 bolts per minute.

Huck 2581

The Huck 2581 is a hydraulic riveter with a pull capacity from 7,400 to 10,700 pounds, depending on the psi. It offers a 0.937-inch stroke and weighs 5.5 pounds.

Huck 940 Powerig

The Huck 940 Powerig is also a hydraulic-powered tool that operates at 5,400-5,700 psi delivering a pull pressure from 2,200 to 2,400 psi. This is a self-contained portable unit weighing 66 pounds and is designed for moderate production and repair applications.

Best Practices for Installation

Once you’re equipped with the right tool for the job, it’s important to use proper technique during the installation process for optimal performance.

Choosing the Right Tool

Different types of fasteners require different degrees of expertise to install. Welds and rivets, for example, require special training and expertise, which makes them more expensive to install. On the other hand, blind bolts are considered to be more economical due to how easy they are to install.

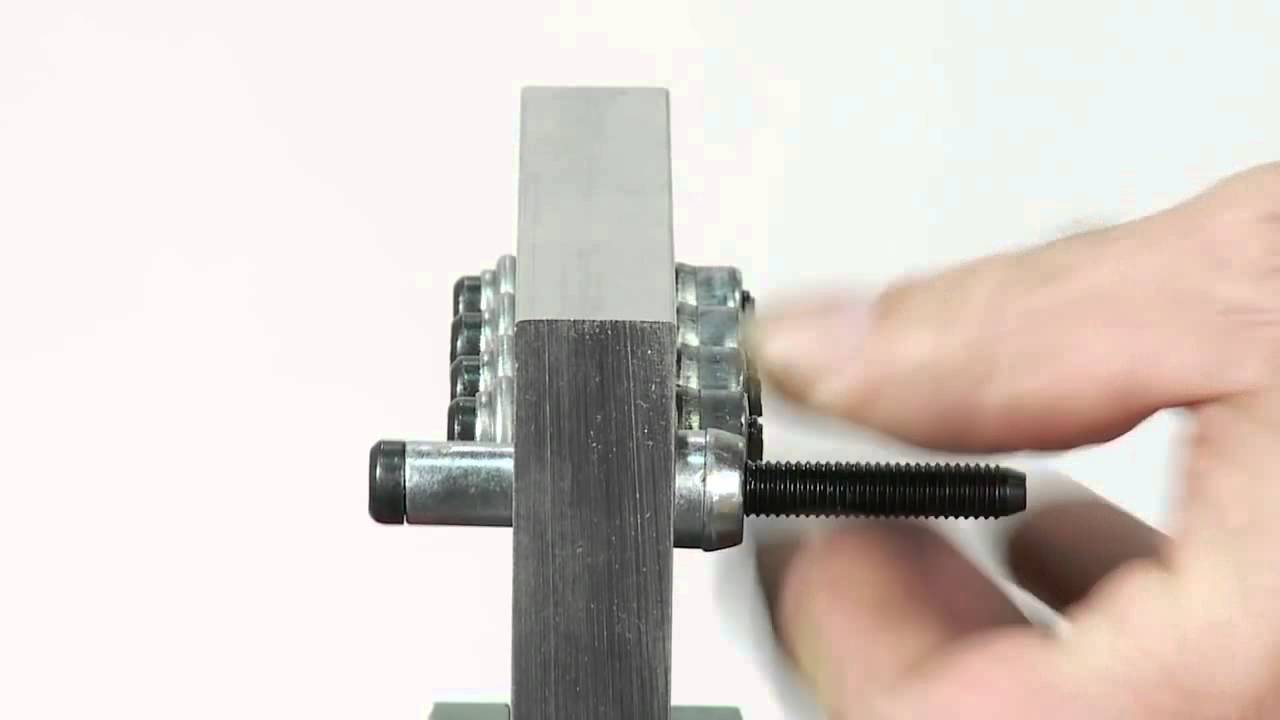

Blind bolts consist of a collar, a sleeve, and a steel pin. To set the bolt, you pull the pin to collapse the fastener sleeve on the blindside, and voila, installation is complete. The collapsing sleeve forms a tight joint on the blind side and the collar is tightened on the facing side. Your tool of choice will even shear off the pin once the bolt is set for a clean finish.

The Installation Process

To install a blind bolt, you’ll generally need to follow these steps:

- Match the hole to the length of the joint, including the thickness of the joint. The grip length from the underside of the collar to the first grip thread determines the strength of any blind bolt.

- Choose the right bolt length, as well as the right diameter for the hole size, to create a solid joint that won’t loosen over time There are many blind bolt fasteners available in different lengths, diameters, and materials. Blind bolts range in size from 3/16 inches to 3/8 inches, or even larger for heavy-duty applications.

- Check the manufacturer’s performance chart to make sure that the bolt you choose has the right tensile strength and shear strength for the job. Tensile strength is the amount of force needed to pull the blind bolt out of its hole. Shear strength is the amount of lateral force along the plane of the bonded material to cause the bolt to fail or break.

- Use the appropriate tool to install.

As you go through the installation process, remember that each tool has different power specifications and different pull pressures, which is why you need to match the tool to the application. The experts at Bay Supply can help you choose the right tool. To help get you started, be sure to read our guide, The Essential Guide to Blind Bolts: Huck BOM and Avdel Avbolt.

Comments