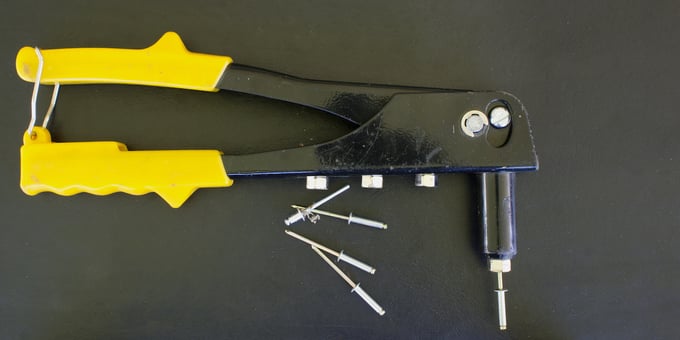

Whether you’re installing an LED sign or repairing a boat, knowing the differences between open- and closed-end rivets is vital. Here are some of the crucial differences to be aware of so you can pick the right blind rivets for your job.

What is an Open End Rivet?

Open-end rivets are hollow blind rivets that are pre-assembled onto a headed pin or mandrel. After installation, these rivets resemble tubular rivets, but in contrast to tubular rivets, the mandrel head stays inside the body of the rivet.

Providing a wide load spread, these rivets provide strong, low-cost fastening and are useful in most industrial riveting jobs. In general, open-end rivets come in dome, large-flange, or a 120-degree countersunk head. These rivets come in a wide range of diameters and lengths suitable for various materials up to 26 millimeters thick. Open-end rivets are available in protruding, dome, low-profile, large-flange, and countersunk head styles and come in a variety of rivet/mandrel material combinations, including:

- Aluminum rivet/aluminum mandrel

- Aluminum rivet/steel mandrel

- Copper rivet/brass mandrel

- Copper rivet/steel mandrel

- Monel rivet/steel mandrel

- Zinc-plated steel rivet/steel mandrel

POP® brand open-end blind rivets are available in aluminum and nickel-copper alloy, and the nickel-copper variety is well suited for environments prone to corrosion, such as the marine industry.

The major benefits of open-end rivets are that they are strong and reliable, versatile, offer a clean installation, and are vibration and tamperproof. Also, you don’t need a skilled operator to install them.

What is a Closed-End Rivet?

Closed-end rivets are a type of tubular rivet with a mandrel through the center and a unique, cup-shaped end configuration that is designed for watertight applications or when stem retention is vital. These rivets can be used in blind or non-blind applications. When set—unlike with open-end rivets—closed-end rivets create a complete seal that prevents liquid or gas penetration. This impressive seal is accomplished through the unique, cup-shaped end configuration of the closed-end rivet.

Closed-end rivets come in domed and countersunk varieties and provide 100 percent mandrel retention, which is vital when setting rivets in electronic equipment or in other electrical applications. With complete mandrel retention, you can rest assured that the head won’t break off and rattle around in your assembly or short out any electronics.

POP® brand closed-end blind rivets offer up to 23 percent greater tensile strength than POP® brand open-end rivets, as well as zero penetration by liquids or gas at pressures up to 100 psi. In general, closed-end rivets are available in a variety of rivet/mandrel material combinations, including:

- Aluminum rivet/aluminum mandrel

- Aluminum rivet/steel mandrel

- Copper rivet/steel mandrel

- Stainless steel rivet/stainless steel mandrel

Other benefits of closed-end rivets are that they are versatile, low cost, strong and reliable without the need for skilled operators, vibration-proof, and tamperproof. Additionally, they offer clean installations that don’t mar material surfaces.

In addition to electronic applications, other uses for closed-end rivets include in setting rivets on LED signs, scoreboards, and recreational vehicles, as well as liquid-handling components such as a hydraulic pump.

The next time you’re shopping for open- or closed-end blind rivets, request a quote from the fastener experts at BaySupply.com

Comments