Vibration-resistant bolts are commonly used when manufacturing of heavy equipment, truck repair, and for other applications in which old-fashioned nuts and bolts won’t stand up to the task. One of the most popular and reliable fastener brands is the Huck bolt from Arconic Fastening Systems.

What makes the Huck bolt so popular for heavy-duty fastener applications is that it is designed to be a permanent joint that resists vibration. Once installed, it won’t loosen up like regular nuts and bolts. Huck bolts offer a clean and reliable alternative to welding, and they are faster and more efficient to install. What’s more, Huck bolts can be used in almost any application in which you need a vibration-resistant fastener, such as trucks and trailers, automotive, rail, agriculture, mining, and oil and gas.

The Birth of the Huck Bolt

The first lockbolt fasteners were patented in 1950 by Louis C. Huck, who developed these bolts for the U.S. Navy and for the railroad industry in 1944 as a means to overcome the problem of bolts loosening due to vibration. The fasteners were branded as Huck Bolts® by Alcoa Fastening Systems, which later became Arconic Fastening Systems. To date, the industry has yet to improve on Louis Huck’s original design.

Whereas conventional bolts are set using a nut, a Huck bolt is set using a permanent sleeve or lockbolt collar that fits around a grooved pin. The collar is fitted into a pre-drilled hole and as the collar is tightened, it is squeezed and forced into the grooves of the pin to swage the collar. The result is a direct, metal-to-metal joint that eliminates transverse vibration and delivers superior tensile and shear strength.

The Huck fastener has a number of characteristics that continue to make it highly attractive for manufacturing and equipment repairs:

- An alternative to nuts and bolts – The swaging of the lockbolt collar creates a permanent joint that will not loosen over time, unlike conventional bolts.

- High vibration resistance – The original Huck bolt was developed to combat loosening of conventional bolts in railcars, ships, and heavy equipment. Conventional nuts have to be retightened, which poses safety and maintenance issues that are solved by the Huck bolt.

- Permanent joint – The Huck bolt forms a permanent, high-strength joint. In fact, the Huck bolt has been tested to provide 10-20 percent higher tensile strength than conventional bolts.

- Simple installation – Huck bolts are easy to install. Huck fastening tools are normally hydraulic, pneumatic, or battery-powered and are matched to the collar size so you simply fit the tool and swage the collar; no special training is required.

- High-speed installation – Because installation is so simple, installation time is shortened. Installing Huck bolts is typically 25-50 percent faster than installing conventional bolts, even when using power tools.

- Additional benefits – There are other benefits that make the Huck bolt especially attractive, including consistent and repeatable pre-loading, a wide bearing collar and head that spreads the load for greater structural integrity, corrosion-resistant coatings, and a lock groove that resists fatigue for longer-lasting joints.

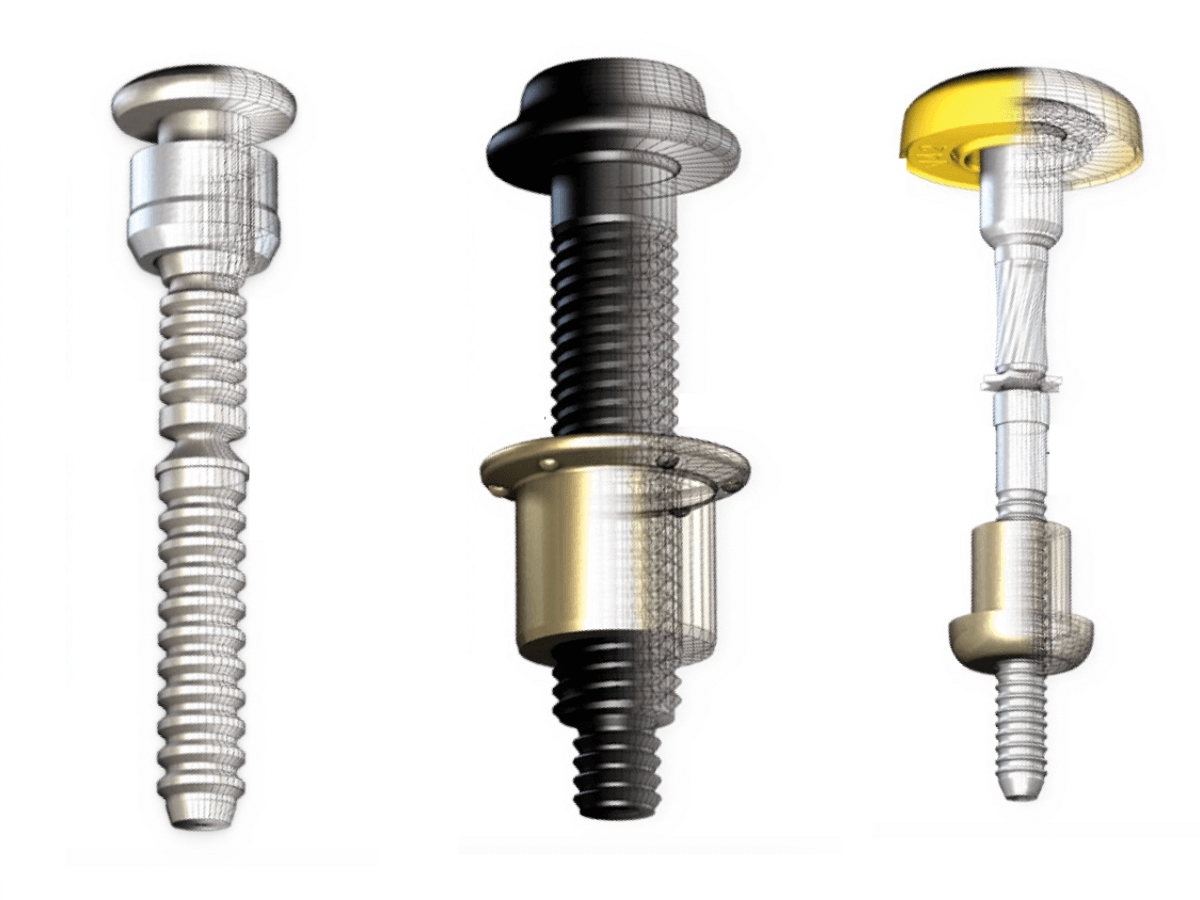

The Three Types of Huck Bolts

There are three basic types of Huck bolt designs, each with its own benefits for specific applications:

- The HuckBolt with pintails is the most commonly used. These Huck bolts have a break point designed into the pin that separates once installation is complete. The excess pin is then ejected or collected by the lockbolt tool.

There are four common types of Huck bolts with pintails: the Huck C6L®, the Magna-Grip®, the Huck C50L®, and the Huck HP8®. The bolts come in a variety of lengths, but the most common diameters are from 3/16-1 3/8 inches. There are various head styles as well, including round and countersunk heads, and the bolts are made of various materials with different finishes. - The HuckBolt without pintails is, as the name implies, designed with a solid pin that has no break point and no leftover metal to collect. Though these bolts do not shear off clean at the collar, installation is done without the shock of pintail removal so there is less operator fatigue. Additionally, cycle time is faster, and there is no exposed metal from pintail removal that could corrode later.

Huck bolts without pintails typically come in sizes ranging from 3/16-7/8 inches in diameter and have round or countersunk heads. Metric sizes are also available. The common types of Huck bolts without pintails include the Huck-Spin® (which has three types: the Original, the Huck-Spin® 2, and the Huck-Spin® 3), the Bobtail® and Bobtail® 2, and the Snap-Tail®. - The reinforced panel HuckBolt is the third type. Specifically designed to prevent cracking and pull-through when used with softer or composite materials, such as GRP vehicle panels, these bolts feature high shear strength and an under-head seal. They also are installed using consistent pressure to prevent crushing the workpiece.

Reinforced panel Huck bolts are generally available in 3/8-inch diameters. They come in a variety of materials, colors, and finishes, and the head styles and diameters vary to accommodate different applications. The Hucktainer® lockbolt and Hucktainer MC® are the most common types of reinforced panel Huck bolts.

If you want to learn more about Huck bolts or aren’t sure which Huck bolt is right for your needs, Bay Supply can help. Our fastener experts are always ready to help you select the right fasteners for the job. Feel free to contact us so we can help you with your fastener needs.

Comments