When you think of industrial fasteners, you usually think of bolts, screws, lockbolts, rivets, and the like. An underappreciated form of fastener is the helical coil thread insert, also known as a helically wound or helicoil insert, which is used to create a threaded surface inside drilled holes. It is easy to install a helicoil insert with the proper tools, and once installed, a helicoil insert can deliver lasting, reliable service even with soft materials.

Before delving into how to install a helical coil insert, we should make it clear that the term Heli-Coil® is actually a registered trademark of STANLEY Engineered Fastening. Like Kleenex for tissues or Xerox for photocopies, the popularity of the STANLEY Heli-Coil has made the term “helicoil” widely used to describe any form of wire-wound threaded insert coil.

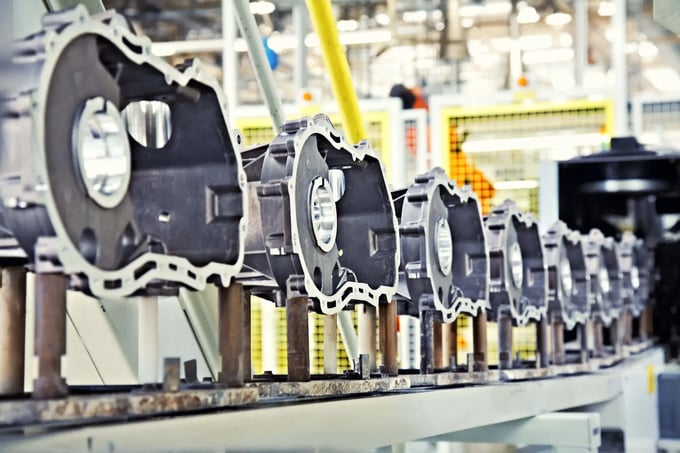

When you need to screw a threaded fastener into a pre-drilled hole, that hole has to have strong threads capable of holding the fastener in place under any load. The helical coil insert is an ingenious invention that can be used to repair stripped threads in steel or other hard metals or to add a solid threaded hole in soft materials such as wood, fiberglass, or plastic. They are also used in construction to provide stronger joints in building frames and even in concrete. When you install a helicoil insert, you screw it into the hole, and the pressure from the bolt or fastener presses the coil against the sides of the hole, creating a strong joint that won’t pull out and that can be screwed and unscrewed as required.

Helical coil inserts come in a variety of materials, including nickel-chromium alloy, phosphor bronze, titanium, and stainless steel. They also come with additives such as silicon and manganese to reduce friction and with various coatings to help provide added lubrication, reduce corrosion, or allow for color identification.

Tanged and Tangless Helicoil Inserts

All helicoil inserts have the same basic shape. They are wound coils that look like springs calibrated to accept the threads of a bolt or threaded fastener. When you install a helicoil insert, you position it in a pre-drilled hole using a special helical coil tool that screws it into place inside the hole.

There are two basic types of helicoil designs, tanged and tangless, which provide different grips to install the coil. The tang is a small segment of the end of the insert that extends into the middle of the coil. With tanged inserts, the tool uses the tang to grip the coil and screw it into place. Once the helicoil is installed, the tang is broken off and removed. Tangless coil inserts do not have a tang but use a driving notch strategically placed in the coil as the means for the tool to grip the coil and position it using the appropriate insert tool.

With tanged helical coil inserts, the tang has to be physically broken off and removed once complete, which is an added step that might leave excess metal that could be caught in machinery. The tangless or tang-free coil insert doesn’t require final tang removal and can be more readily adjusted or even removed intact.

Installing any helicoil insert requires the same basic steps. First, you drill the hole and then the tap hole to provide a threaded track for the coil. The coil itself is then placed on the end of the appropriate nosepiece, depending on whether you are using a tanged or tangless coil insert. The insert is then screwed into place and, if necessary, the tang is removed. If you are repairing a stripped hole, the process is even easier because you merely have to re-tap the hole and insert the coil.

Popular Helicoil Installation Tools

There are a wide variety of coiled thread inserts manufacturers and insert tools. For simple jobs, you can use a manual coil insert tool. Recoil®, for example, manufactures a range of handheld coil insert tools and helical coil repair kits.

KATO is one of the best-known manufacturers of threaded coil inserts and tools. KATO offers the CIM and KPHM manual tools for easy insertion and removal of threaded coil inserts with the turn of a crank. In addition, KATO offers the Perma-Coil manual coil repair kit.

KATO also offers a variety of handheld electric installation and extraction tools for every application. For higher-volume installations, KATO has the Prewinder Air, which is a pneumatic installation tool with an air motor, adapter, and front-end assembly that can be used with coil inserts from 1/2-inch to fine thread sizes.

Coil thread inserts are highly versatile and can be used in a wide range of applications and installed using a variety of tools. To learn more about helical inserts, be sure to download The Essential Guide to Coil Threaded Inserts.

Comments