Blind rivets are among the most popular types of fasteners because they are strong, long-lasting, and easy to install. The basic design of blind rivets consists of a two-piece assembly with a sleeve or rivet body and a mandrel. To install, you insert the blind rivet in a pre-drilled hole and use a blind rivet tool to pull the mandrel to bring the two workpieces together and collapse the rivet body on the blind side of the hole. Then, the tool snaps off the mandrel to finish the installation.

Although the basic design is the same, blind rivets come in various configurations, sizes, and materials. The most popular blind rivet is the pop rivet, which was initially used in 1934 for aircraft manufacturing. They are called pop rivets because of the popping sound they make when installed. Pop rivets are ideal for assembling aluminum aircraft since they can be installed from one side (which is why they are called blind rivets).

After nearly a century, pop rivets are still the most common blind rivet used for manufacturing and applications across many industries. Stanley owns the POP® brand name, but many fastener manufacturers use the same blind rivet design. To get optimal blind rivet performance, you want to choose the right blind rivet size for the job. Here are some things to consider when determining blind rivet size.

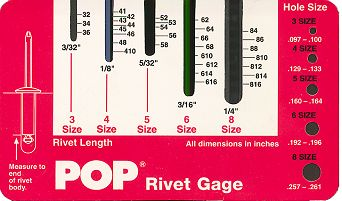

Blind Rivet Diameter and Hole Sizes

Diameter is a crucial factor when choosing the proper pop rivet for your application. Choosing a rivet that’s too narrow for the hole can leave a gap, which can increase shear stress or cause installation problems. The blind head could also expand in the space between the two workpieces. If you use a rivet that is too wide for its hole, it will be harder to place and result in a poor fit. Never force a blind rivet into any hole that doesn’t match its diameter.

Rivet Hole Size Chart

Blind Rivet Body Length

The body length of a rivet is its total length (not including the head). Body length is different from the grip range, but it is an important measurement. You need to consider the clearance of the rivet on the blind side of the material being fastened. A blind rivet that’s too long may not fit correctly or could negatively impact whatever resides behind the hole.

Blind Rivet Grip Range

The grip range is the thickness of the material that the rivet must fasten. For example, if you are attaching two ¼-inch pieces of metal, you will require a blind rivet with a minimum grip of at least ½ inch. When considering grip range, best practice dictates that you choose a rivet that doesn’t exactly match the minimum or maximum points. It’s better to choose a grip range that is comfortably in between to ensure optimal shear and tensile strength and improve the longevity of the setting tool.

Rivet Head Sizes

Use flat-head rivets if you want the joint to be flush with the fastened material. Dome head rivets reside above the material. If you're going to cover more surface area for extra fastening security, you can use large flange rivets. It’s essential to consider the blind rivet head size to determine the final joint's integrity, protrusion, and aesthetic value.

Choose the Right Blind Rivet for the Job

Determining the best blind rivet size for the job is extremely important. And it’s equally important to choose the right blind rivet style for the application. Here are some of the most common types of blind rivets:

- Closed-end rivets: These blind rivets come in two pieces, are extremely versatile, resist vibration, and make for clean installations.

- Open-end rivets: Also known as nail rivets, open-end rivets differ from closed-end rivets because they don’t create a sealed joint, which is required to contain gas or liquid.

- Micro rivets: These are smaller rivets with a diameter of 2 mm or less and are perfect for specialty applications such as mounting printed circuit boards and electronic applications.

- Multi-grip rivets: Multi-grip rivets have a wider grip range than standard pop rivets and can accommodate oversized and irregular-sized holes.

Choosing the right blind rivet size and type, as well as the material from which the rivet is made, will give you greater success no matter the application. Choosing the proper rivet ensures that the rivet will endure for a long time.

To learn more about the different types of blind rivets and their applications, download The Essential Guide to Blind Rivets.

Comments