If you are familiar with fasteners, then you know pop rivets are among the most popular blind bolts. Pop rivets are easy to install and create a lasting joint that will resist vibration. However, as with all types of rivets, you must choose the right pop rivet for the application and the right pop rivet tooling option to install it.

Pop rivets are used in a variety of applications and for a wide array of materials. They can be used to fasten metal, plastic, wood, and leather and are often used to connect different materials, such as plastic to metal. Pop rivets are used in everything from manufacturing cars to consumer electronics.

Given the wide range of applications, choosing the right pop rivet gun is essential. You want to choose a rivet tool that will install fasteners snugly but that won’t crush the materials. There are many pop rivet tooling options to choose from, including manual, cordless, and high-powered pneumatic tools.

The Story of the Pop Rivet

Before reviewing the types of pop rivet tooling options available, let’s quickly review the origin of the pop rivet. The Tucker Eyelet Company, makers of hooks and eyes for boots, created the pop rivet. In 1934, the company was asked to develop a new type of fastener for aircraft manufacturing, and the pop rivet was born.

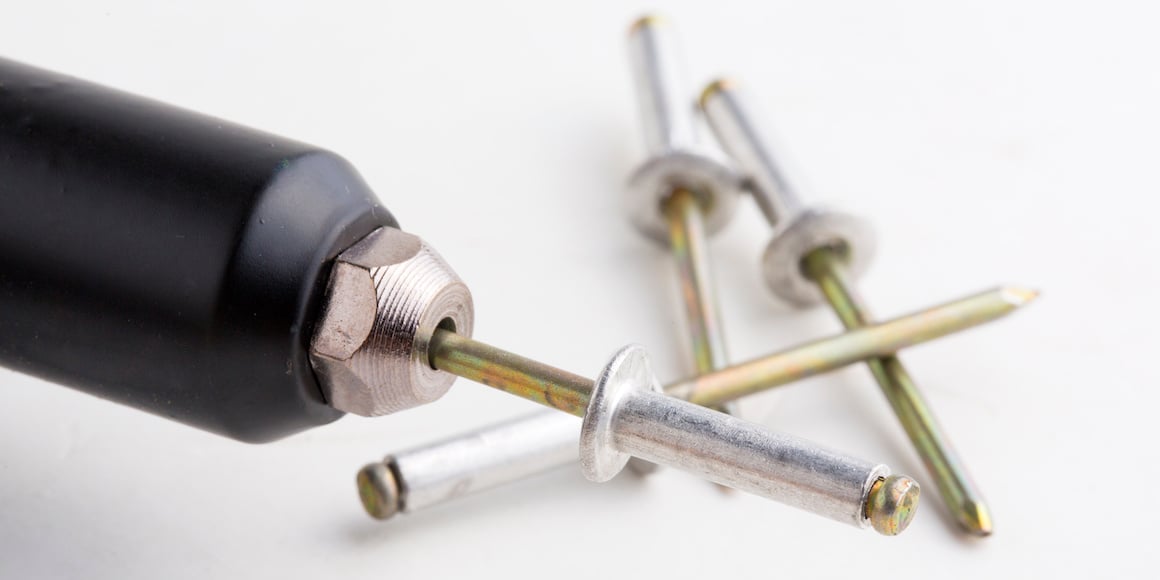

In the 1930s, they were one of the first blind rivets, which could be installed from one side of a workpiece. They are also lightweight, easy to install, and have a rounded head for better aerodynamics. A pop rivet consists of a shank and a mandrel and can be installed in any pre-drilled hole. It’s often used instead of nails or screws.

In the 1930s, they were one of the first blind rivets, which could be installed from one side of a workpiece. They are also lightweight, easy to install, and have a rounded head for better aerodynamics. A pop rivet consists of a shank and a mandrel and can be installed in any pre-drilled hole. It’s often used instead of nails or screws.

Since then, STANLEY Engineered Fastening acquired Tucker Eyelet Company, and the term pop rivet has become synonymous with a type of blind fastener, even though Stanley holds the registered trademark.

Different Pop Rivet Tooling Options

Just as applications for pop rivets have evolved, so have pop rivet tools. There are three basic categories of pop rivet tooling: pneumatic, cordless, and manual. Each type of rivet tool has advantages and disadvantages, so understanding the differences can help you choose the right tool for your next job.

Pneumatic Rivet Tools

Most people prefer pneumatic tools for heavy-duty manufacturing, such as aircraft or automobile assembly. A hose connected to a compressor powers pneumatic tools and can be set to a specific power setting, depending on the application. These tools are big, powerful, and used on assembly lines or where you need fast, reliable, and consistent rivet installation. The need for an umbilical hose to power the tool limits use to a place where you can have a compressor, such as a factory or machine shop.

Some of the most popular makers of pneumatic pop rivet tools are FAR, Gesipa, Lobster, and Stanley.

Cordless Rivet Tools

Pop rivets are increasingly being used on jobsites and in the field for construction, solar panel installation, truck repairs, and other uses. Since using pneumatic tools in the field is impractical, tool makers have been developing more powerful cordless rivet tools.

The adoption of lithium-ion batteries has revolutionized portable power tools. Li-ion batteries are lightweight, deliver more power, hold a longer charge, and recharge quickly, making them ideal for portable rivet tools. Manufacturers are also working to standardize battery and charger designs to make them interchangeable. Many battery-powered tools deliver almost the same power as pneumatic tools and can accommodate many nosepieces.

The most popular makers of cordless rivet tools are Avdel, Gesipa, Huck, and Stanley.

Manual Rivet Tools

Handheld pop rivet tools still have their place. Occasionally, you need to install just a few pop rivets or make a simple repair. In those instances, a manual rivet tool may be exactly what you need.

Manual rivet tools have handles like a pair of pliers. To install the rivet, you set it in the nosepiece, place the rivet in the hole, then squeeze to set the rivet. Many manual rivet tools have long handles to provide more leverage for rivet installation. Some manual rivet tools, such as the Goebel-25-SN, feature a lazy-tong design; all you have to do is set the rivet and push to set it.

Several toolmakers are offering manual pop rivet tools. Some brands to look for are Avdel, Cherry Aerospace, FAR, Gesipa, Goebel, Huck, and Marson.

Pop Rivet Tooling Options from Bay Supply

Choosing the right pop rivet tools isn’t difficult. Consider how you will use the tool and what types of nosepieces you will need, and check the specifications for stroke length, pull force, and other particulars. You may also want to consider the tool's weight, cycle time, battery life, and how long it takes to charge.

Since there are so many pop rivet tools to choose from, it pays to get expert advice. The professionals at Bay Supply can help you choose the right tool for your needs. Contact us for a quote today.

Comments